Minerals are concentrated into a slurry that is about 15% copper.

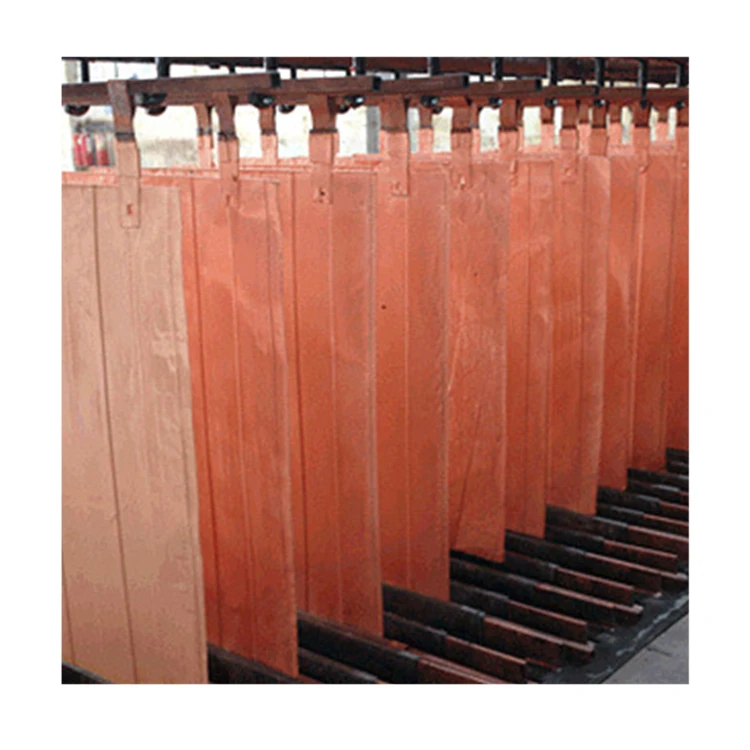

Sulfide ores are moved to a concentrating stage, while oxide ores are routed to leaching tanks. The beginning for all copper is to mine sulfide and oxide ores through digging or blasting and then crushing it to walnut-sized pieces.Ĭrushed ore is ball or rod-milled in large, rotating, cylindrical machines until it becomes a powder usually containing less than 1 percent copper. Below is a quick description of the path. When it is recycled it can pass through some over and over again. It is therefore essential that, during shipping and transportation, they are not contaminated with any extraneous materials.Ĭopper Production from Ore to Finished Productįrom its original home buried underground in a mine to its use in a finished product such as wire or pipe, copper passes through a number of stages. Copper is also used in the production of brass, copper tube, copper sheet products, and found in over 450 alloys.Ĭopper cathodes are used as a raw material feed for the production of high purity copper and copper alloy products. Copper cathode is the primary raw material input for the production of copper rod for the wire and cable industry. Individual cathode sheets are manufactured to different dimensions by different suppliers in the range of 0,5 m 2 to 1 m 2 and 3 to 20 mm thick, with or without ‘ears’.

0 kommentar(er)

0 kommentar(er)